Key Challenegs in Manufacturing

Low Level of Production Informatization

Lack of real-time and scientific production working hours management

Lack of process quality monitoring

Abnormal detection relies on manual intervention

Lack of AI and algorithms to support intelligent manufacturing

Lean AI iSOP Value Proposition

Solution

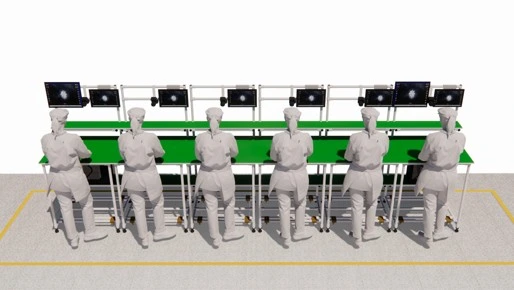

Industrial Lean AI Integrated Hardware & Software Solution (Worker Digital Twin)

- Edge AI-enabled smart tablets + edge computing servers.

- Machine vision AI for workstation action and image recognition.

- Smart work-hour management, intelligent SOP generation, AI-powered training, and data-driven decision-making.

Business Value

- 30% increase in production efficiency, 30% improvement in management efficiency, and 20% reduction in quality losses.

- Empower traditional manufacturing industry with digital intelligence

- Integrating AIoT hardware and software (tablets, chips, ERP, MES, etc.) across the supply chain, leveraging cloud data and machine learning to enhance AI capabilities, boost efficiency, scalability, and profitability.

Use Case

Workstation efficiency and quality improvement in manual manufacturing

- SOP generation and intelligent training across industries

Safety compliance detection and proactive alerts across industries.

Lean AI iSOP Value Proposition

Solution

Industrial Lean AI Integrated Hardware & Software Solution (Worker Digital Twin)

Business Value

30% increase in production efficiency, 30% improvement in management efficiency, and 20% reduction in quality losses. Empower traditional manufacturing industry with digital intelligence Integrating AIoT hardware and software (tablets, chips, ERP, MES, etc.) across the supply chain, leveraging cloud data and machine learning to enhance AI capabilities, boost efficiency, scalability, and profitability.

Use Case

Workstation efficiency and quality improvement in manual manufacturing SOP generation and intelligent training across industries Safety compliance detection and proactive alerts across industries.

How AI iSOP Works

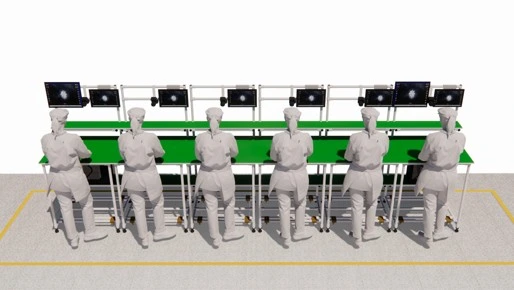

Smart PAD H11 setup at production lines as windows to collect data

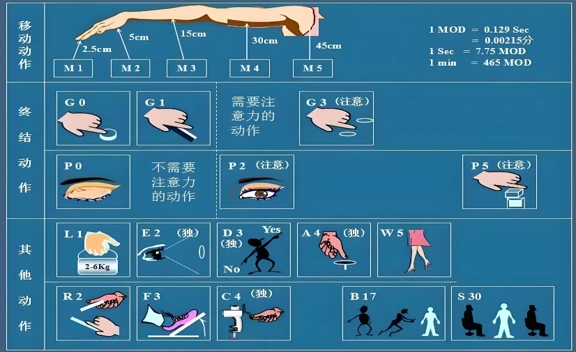

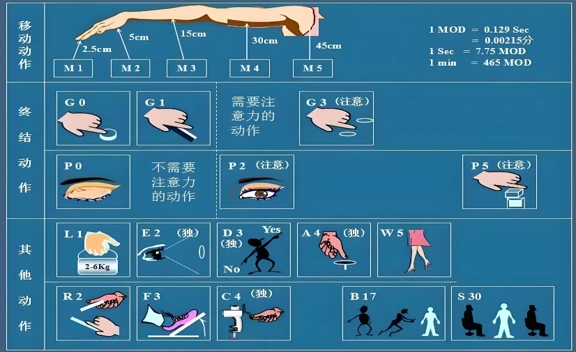

Production line SOP disassembled into movement cells following IE standards acts as basis of intelligent data application.

AI model and application of Industrial vision and motion empowers intelligent production and efficiency improvement

How AI iSOP works

Smart PAD H11 setup at production lines as windows to collect data

Smart PAD H11 setup at production lines as windows to collect data

Smart PAD H11 setup at production lines as windows to collect data